Osmosis treatment

For osmosis treatment, the existing gel-coat is removed from the side of the boat. There are several ways of removing the gel-coat from the hull. Sand blasting, flexing, sanding, heat peeling or using a special milling tool. The special milling tool which we use has the clear advantage over all other options in that it leaves a completely smooth surface after peeling (the milling depth can be precisely set and maintained during milling), and the use of fillers is reduced to a minimum.

mill

mill milled boat hull

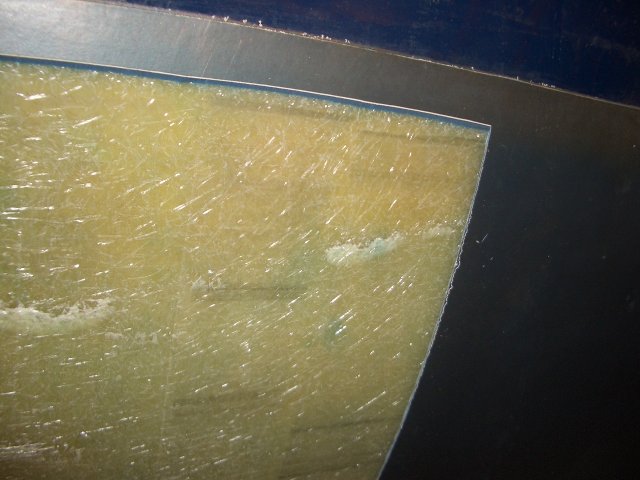

milled boat hull laminate

laminateIf the osmosis has progressed to such a severe degree that the laminate is badly weakened following the milling process, or is too thin due to individual bubble formations, we will reconstruct the hull side using additional, new laminate layers. This is not usually necessary, since osmosis is usually treated long before this stage is reached. It is very important that prior to reconstruction, the open laminate is thoroughly washed out with water, in order to remove all trace of acids and resin residues, and that it is completely dry. Here, it is of no consequence whether the boat has 6 months or 6 days to dry. The only important factor is that the laminate is completely dry. We are able to monitor this process using special measuring devices.

For osmosis treatment, we use West System materials. Epoxy resin is mixed in an optimum manner with the different additional components in order to construct the hull underbody. Among other things, for the layer construction using an additional aluminium blocking layer, which guarantees absolute water tightness.

washing

washing rebuilding

rebuilding finish

finishWhen constructing the hull underbody, it is important that if appropriate, the required filler is applied directly after the open laminate is sealed, and not at the end, since this is then also covered in an absolutely watertight way by the subsequent reconstruction using several layers. Naturally, the filler also has an epoxy basis.

We provide a guarantee of six years on every hull underbody which we have treated for osmosis! We can make you an individual offer regarding the prevention or treatment of osmosis for your yacht.